ERLO Units

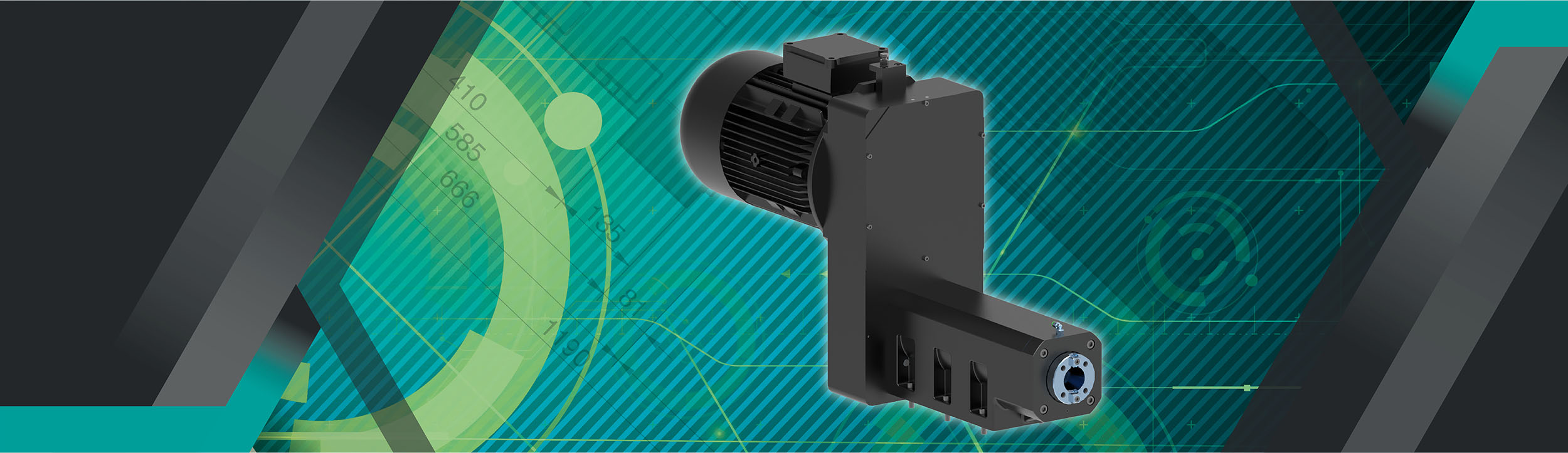

Machining units

Machining units

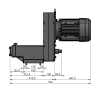

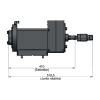

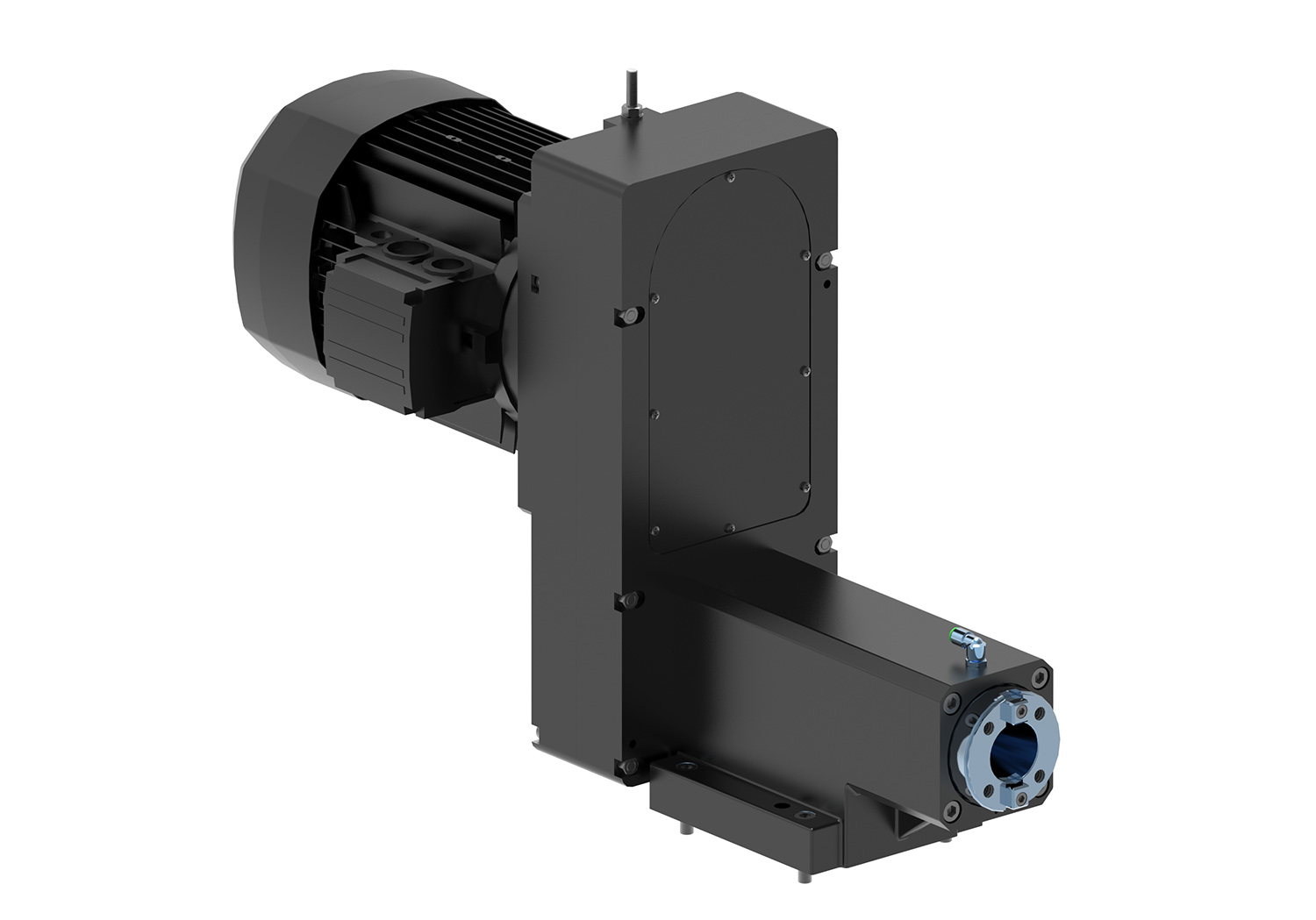

Machining units CG.30

- For modular assembly

- Cone: ISO 40 / BT 40

- Drilling capacity: Ø35

- Tapping capacity: M24

More product information:

| Features | CG 30 |

|---|---|

| Main cone | ISO 40 / BT 40 |

| Axial load capacity | 5800 N |

| Radial load capacity | 3200 N |

| Maximum torque | 200 Nm |

| Maximum RPM | 6000 rpm |

| Drilling capacity (600 N/mm2) | Ø35 |

| Tapping capacity (600 N/mm2) | M24 |

| Lubrification | Grease (free maintenance) |

| Cone pressurisation | Maximum 2 bars |

| Concentricity | 0,01 mm |

| Weight (without motor) | 65 KG |

| Rotary joint | Pneumatic release |

| Minimum unclamping pressure: 3.3 bar | |

| Tool clamping force: 12 kN (DIN 69871) | |

| Tool clamping force: 10.5 kN (MAS 403 BT 45°) | |

| Automatic tool clamp | 1 coolant passage channel (max. 60μm) |

| Cutting fluid, oil, MQL | |

| Max. pressure 70 bar (MQL 10 bar) | |

| Encoder | 4,096 pulses |

| A+, B+, R+, A-, B-, R (zero pulse) |

Settings system

| CG.30 | AM | 601 | 0 | 0 | - | B | 1 |

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 |

1 - Tool clamp

- AM: Mechanical clamp

- AA: Pneumatic clamp MAS 403-1982 BT/PT2 (45º)

- AB: Pneumatic clamp DIN 69871/69872

2 - Transmission

| R.P.M | TORQUE (Nm.) | Transmission | Motor | |

|---|---|---|---|---|

| 601 | 927 | 16 | 1,3/1 | 1,5 kW 700 r.p.m. |

| 602 | 836 | 17 | 1,2/1 | |

| 603 | 700 | 21 | 1/1 | |

| 604 | 506 | 28 | 1/1,4 | |

| 605 | 471 | 31 | 1/1,5 | |

| 606 | 332 | 44 | 1/2,1 | |

| 607 | 1854 | 20 | 1,3/1 | 4 W 1400 r.p.m. |

| 608 | 1673 | 22 | 1,2/1 | |

| 609 | 1400 | 26 | 1/1 | |

| 610 | 1026 | 36 | 1/1,4 | |

| 611 | 943 | 39 | 1/1,5 | |

| 612 | 665 | 56 | 1/2,1 | |

| 613 | 1218 | 17 | 1,3/1 | 2,2 W 920 r.p.m. |

| 614 | 1100 | 18 | 1,2/1 | |

| 615 | 920 | 22 | 1/1 | |

| 616 | 674 | 30 | 1/1,5 | |

| 617 | 610 | 37 | 1/1,7 | |

| 618 | 437 | 42 | 1/2,1 | |

| 619 | 3800 | 15 | 1,3/1 | 4 kW 2870 r.p.m. |

| 620 | 3430 | 18 | 1,2/1 | |

| 621 | 2870 | 24 | 1/1 | |

| 622 | 2043 | 28 | 1/1,4 | |

| 623 | 1923 | 31 | 1/1,5 | |

| 624 | 1364 | 28 | 1/2,1 |

3 - Encoder

- 0: Head without encoder

- 1: Head with encoder voltage 5VDC±5%TTL/RS42

- 2: Head with encoder voltage 10…30VDC, HTL/PP

- *NOTE: Encoder not available for head with mechanical clamp

4 - Interior cooling

- 0: Head without interior cooling

- 1: Head with interior cooling

- *NOTE: For units with automatic tool clamping, the tool's internal cooling system is included by default.

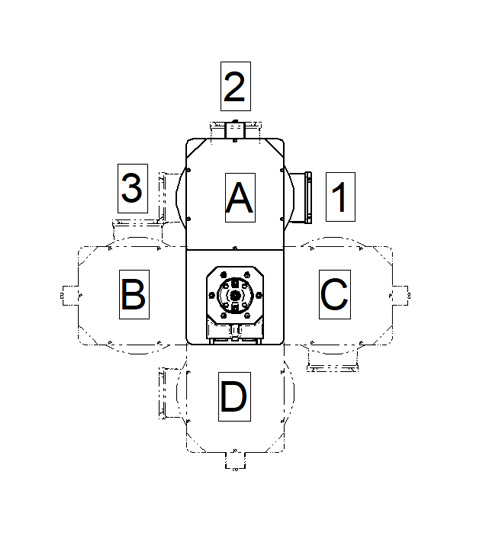

5 - Pulley housing orientation

- A, B, C, D

6 - Orientation of the motor terminal box

- 1, 2, 3

Do you want us to call you?

Leave us your information and we will call you to clear up your questions