The very first failproof thread checking machine.

INTERCEPTOR combines linear and rotary movements in a single integral solution enabling work to proceed with a greater level of control.

The maximum rotation torques range from 1.5 Nm to 8.9 Nm and the position tolerance is +/- 0.05 mm.

Slower pushing movement with the unit stopped until engaging with the control.

Rotates in a counter-clockwise direction, with controlled linear pressure, to find the lead-in thread.

Reverses the rotation direction to start checking the thread.

Produces a linear movement, pushing with an established strength, rotating at controlled revolutions and with a torque limiter.

During the checking process it checks the position and measures the torque. On reaching the programmed position, it reverses the rotation and retracts. We measure the torque throughout the process. If the position achieved and the measured torque values are correct, the part is approved. If the measured torque exceeds the programmed parameters, or if on the contrary, they are lower, the part is rejected.

When it reaches the torque limit, it rotates in the opposite direction to end the checking cycle.

Depending on the linear position at the moment of maximum torque, the robot decides whether the part is good or bad, and either rejects it or deposits it in the approved parts container.

An example is worth more than a thousand words:

The possible applications in the production process are completely flexible.

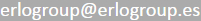

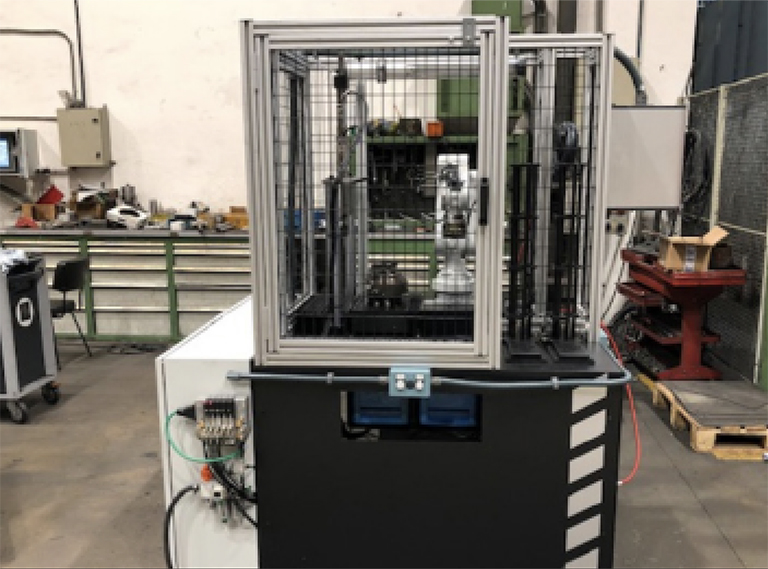

Stand-alone thread checking machine, for integration into the work cell.

Thread checking machine integrated within a transfer machine manufactured by Ibermach.

Thread checking system as a production machine.

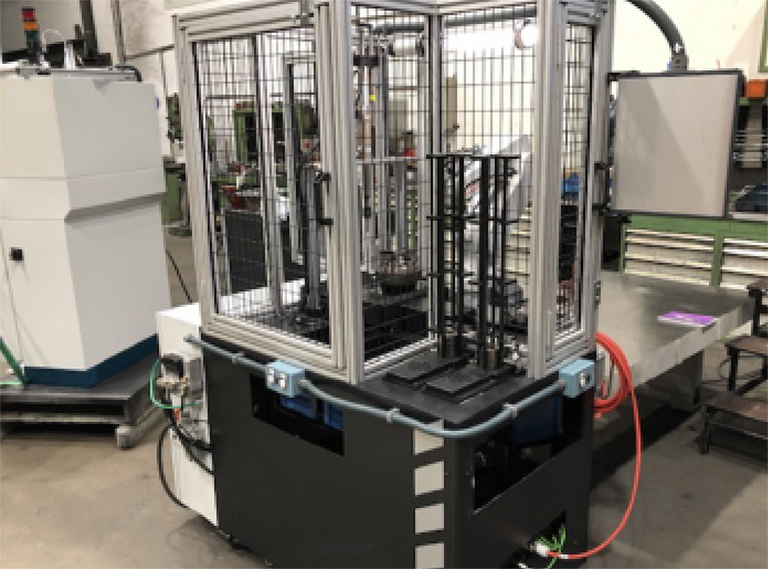

Thread checking system beside the production (transfer) machine, taking advantage of the part feed robot.

We have developed this solution in response to an obvious market need. Interceptor represents a before and after in thread checking.

| Checking method | Thread functionality | Thread quality | Thread existence | Tool wear | Go control | Preliminary hole measurement |

|---|---|---|---|---|---|---|

| Manual tampon |  |

|

|

|

|

|

| Artificial vision |  |

|||||

| Sensorics |  |

|||||

| Servo motor torque control |  |

|

|

|||

|

|

|

|

|

|

|

Why add INTERCEPTOR to your production chain?

It prevents human error and penalisations from customers due to rejection.

It is flexible and modular for addition to your production process.

It has very high productivity and rapid amortisation.

It guarantees the absence of rejections.

Has the time come to form an alliance with Interceptor?

Contact us